NewsroomWaste Disposal for Ion-Exchange Water Plants

-

Blog

Blog

Ion exchange is a commonly used water treatment technology where one or more unwanted ionic contaminants are removed from water by exchange with another non-objectionable ionic substance. Both the contaminant and the exchanged substance must be dissolved and have the same type of electrical charge (positive or negative). An example of ion exchange familiar to most consumers is “water softening”, which softens by exchanging calcium and magnesium with sodium. Ion exchange is commonly used by municipalities in Kansas for treatment of hardness, nitrates, arsenic, and radionuclides. Waste disposal for ion-exchange water plants allows for several different options and working with an engineer will help your city decide what’s best for your community.

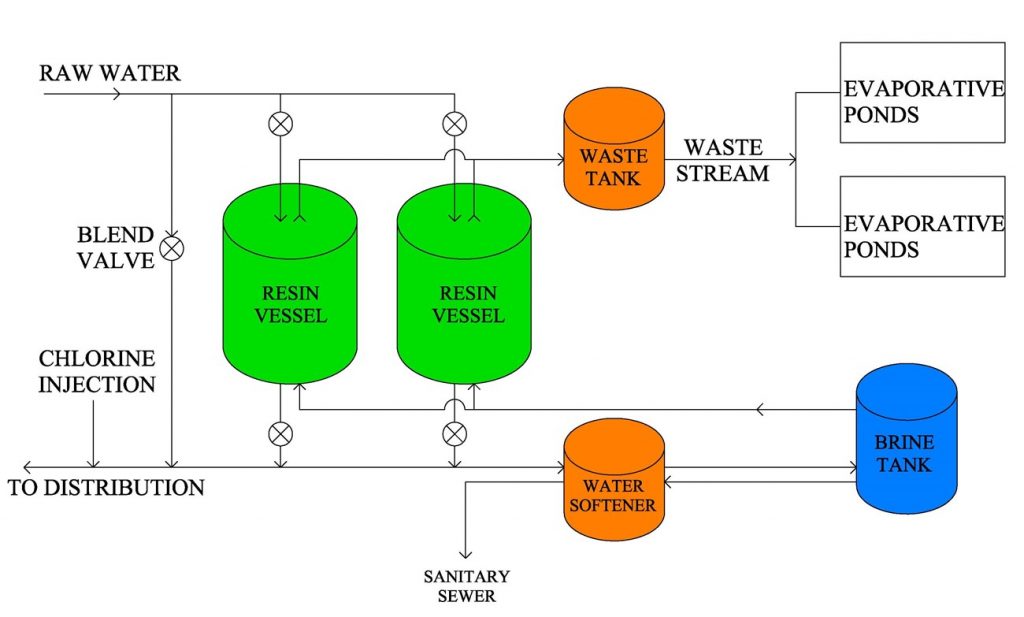

Here is a simplified ion-exchange schematic that depicts how municipalities treat their water for their communities.

Raw water is treated before use and goes through the system above. Around 95-99% of the water treated will be sent on to distribution; however, the remaining percentage must be disposed of as a concentration of brine and removed contaminants.

KDHE requires a waste stream summary for all projects that produce a waste stream. There is additional information on their website here, that further explains their process and what’s required for each municipality before starting a project. There are different disposal methods, and whichever one your community chooses must be approved through KDHE. KDHE will provide guidance and feedback on which methods are acceptable for your project. Your project consultant will be fundamental in preparing the waste stream summary and coordinating its review through KDHE. EBH Engineering has the resources necessary to complete these types of review.

There are several disposal options as it relates to your ion-exchange waste disposal. Option one includes discharging to municipal sewer systems, but rarely is this method acceptable. Not only must the concentration of contaminants be acceptable for treatment at the wastewater plant, but the high salt concentrations must be acceptable also. Bottom line: salt and wastewater plant biology do not get along. Another option includes disposal via injection wells which is injecting hazardous and non-hazardous backwash below the lowest drinking water producing zones. There are high construction costs (think 7 figures) and high operation and maintenance costs when utilizing this method. This may be the only option if you are needing to remove radionuclides. A third option is discharging to a river, which requires a NPDES Permit. You may be able to go this route with slightly concentrated waste such as Reverse Osmosis plant reject water, but this is not an option for brine wastes associated with ion-exchange.

The fourth option is discharging to a double lined evaporative lagoon. There are some pros and cons to double lined high-density polyethylene (HDPE) evaporative lagoons.

Pros:

- KDHE is typically Agreeable

- No Discharge Permits

- Reduced Maintenance

- Low/No Odor

Cons:

- Concentrations Increase with Time

- Operation Affected by Precipitation

- Evaporation Varies by Year

- Large Footprint

- End-of-Life Closure Issues

There are some design considerations for evaporative lagoons that include:

- Quantifying inflows and outflows

- Proper Safety factors

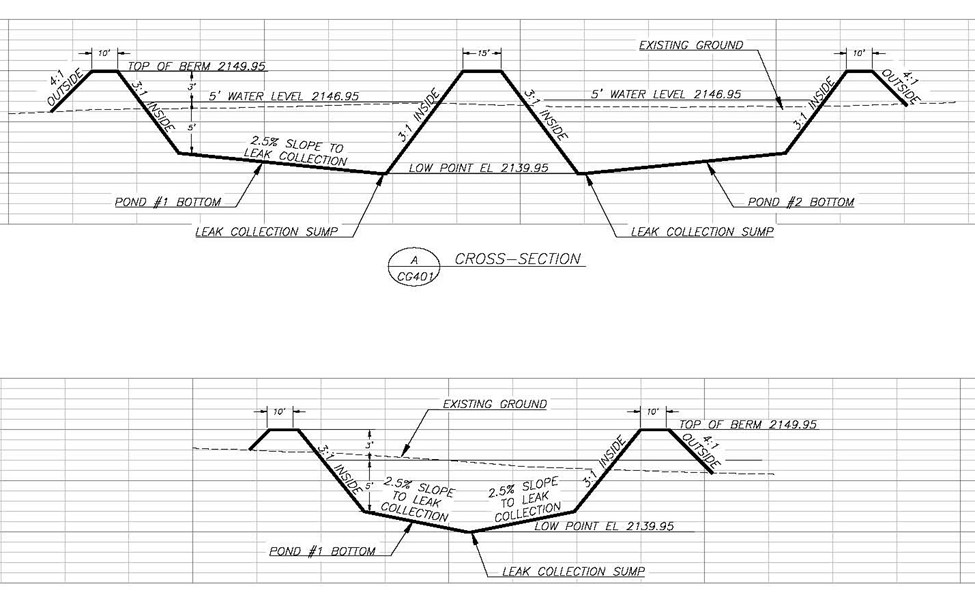

- Use a 2-cell design for proper redundancy

- Utilize 60-mil thickness HDPE primary and secondary liners

- Utilize a 200-mil intermediate geogrid for leak collection

- Maximum 1/64” per day seepage

- Incorporate leak collection between primary and secondary liners

As a municipality there are some other details in the design that are good to consider which include:

- Salt content will build up over time

- Account for analyzer wastes

- Mother nature has a mind of its own

- Install gravity flow (6” + pipe), if possible

- Bring pipe into lagoons above normal water level

- Use textured liner on exposed surfaces

- Build tall fences to keep deer and wildlife away

- Use a 16’ wide center berm

If you are having issues with water level rising, there are some things you can do to troubleshoot this problem. Those include:

- Optimize the treatment process

- Increase bypass

- Reduce/divert analyzer flows

- Set up emergency transfer to STF or neighboring facility (this must be coordinated and approved by KDHE)

- Increase evaporation

Additional issues can also occur with evaporative lagoons, and there are somethings you can consider looking into. If you suspect leaking, you may need to look at pipe penetrations through the liners. If your lagoon is going dry, make sure sandbags are installed at the bottom of the lagoon or pump fresh water in for ballast. Wind can cause the liners to inflate like a huge balloon, so make sure the liner is secured. If your waste flow rate is reduced, you may have scale build-up in the force main to the evaporative lagoons. You may need to soften the water. Using a large diameter gravity line will also help with force main plugging.

There are several disposal options, as mentioned above, but it must be determined which is the most appropriate for your community and your project. Contact us today.

-

Michael Younger, PE

Michael Younger, PE